Obsidian Protocol: Produktionsupdate

Es gibt Neuigkeiten von Obsidian Protocol.

Since the outbreaks in Beijing are now under control, we’ve been able to continue our work. We hope that more restrictions could be lifted in this summer.

First of all, we want to make a formal apology for the delay of updates. We ask for your understanding, because we would never give up on this project and we’re doing our best concerning the situation these days. The process of detachment and die sinking is more complicated than we had expected, but we’ll manage both in the end.

Some parts of the updates this time were shown in a single picture in the QQ-group and twitter during development period. We have been advised that we could post little progress onto the update pages from time to time. There would be smaller ones following.

Please allow me to make a brief introduction on how a mould of plastic will be produced step by step after the manufacturer has been determined, including:

- Ordering

- Adjusting design

- Modifying 3D models

- Building industrial models

- Parting

- Adding details and adjustment

- 3D printing

- Transferring data to the factory

- Producing the mould

- Trial production and modification

It might sound cumbersome, but actually these procedures are being carried by our studio members, engineers along with the mould makers together. Therefore, it’s a rolling process. In addition, it’s the first time we’ve gone through the whole process, so we’d like to apologize again for wasting too much time in the earlier stage.

1. Ordering

After we sign the contract with the factory, the total number of moulds has been agreed upon by both sides. So, the first thing we need to do is to optimize the order of the parts on different frames.

In this process, we need to confirm how many moulds will be needed and what parts will be placed on each mould.

Here’s a rough CAD figure, showing the moulds arrangement of the Reconstruction and Development League in the earlier stage. Those of the United Network and the Guardians of Freedom are similar.

As shown in the figure, there will be 4 frames of parts on each moulds. By doing so, we could pack all the frames in small boxes and apply different configuration to different packages.

In this step, we need to confirm how much area each part occupies on a moulds and how many parts there should be. After the work is done, we wouldn’t change the proportion unless necessary. Since the distribution of the whole project depends on the number of parts in each package, adjusting proportions will definitely lead to unnecessary changes as well as too much trouble for follow-up work.

2. Adjusting design

In the crowdfunding stage, all the pictures we showed were basically original designs of the miniatures. If you look closely, you will find that the details are quite casual and the structure is rather schematic.

Also, the original design might conflict with the logic of parting, or some details are too small or too fragile to be manufactured. As a result, we need to make adjustments in the production stage.

We were content with some modules, but we wanted to refine on the others. As for those, we basically redesign them from scratch.

This rifle was a special case. At that time, we wished to explore the whole Reconstruction and Development League based on this module.

Most modules wouldn’t be redesigned again and again. Sometimes we made specific requirements on certain modules, and we outsourced them to excellent designers. For example, the redesign of the shield was conducted by Jason·Song! In the future, we will display more works from different designers.

3. Modifying 3D models

Once the design adjustment is done, we will modify the 3D models. In this stage, the overall logic of parting will be formed. In order to ensure that the appearance is pleasant, we need to adjust the proportions repeatedly. So, the whole process is still carried out in MAYA.

Sometimes the volume is unclear, or we couldn’t be sure about the outcome. Then we would 3D print some models to test the results.

When the design is considered complete, we could move on to industrial modeling.

4. Building industrial models

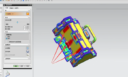

At present, in the optimized workflow, we use different colors to mark the parting logic of MAYA models. Then our modeling experts will start to make industrial models in Rhino.

The picture above shows the initial industrial model of the outer armor parts of Lei-Gong. The models in this stage don’t involve much detail. Our priority is to make sure that the model itself is neat and correct so that the parting process wouldn’t be troublesome.

In addition, since the modules could be changed manually, it’s important to consider and test whether it is influenced by the assembly.

5. Parting

Parting means dividing the whole model into separate parts, which requires both skills and experience. It’s fair to call it the soul of model designing.

On one hand, we need to make sure the parting logic is easy to understand. On the other hand, because our project is a miniature wargame and we want the players to be able to assemble several models in a short time, the number of all the parts should be limited to a certain level.

The parting of the miniature of Wild-Dog is done, but more details will be added. As can be seen in the figure, we divided the torso into only two parts, just to simplify the assembly process.

After parting the model, it’s necessary to remove some parts to make sure the thickness of the whole part is uniform and to prevent Sink Mark. Then, the assembly holes and locating dowels will be added.

Gaps ranging from 0.05mm to 0.15mm should be set between rotatable axes, fixed axes, locating dowels, staggered structure and magnet opening. As for the surfaces which are parallel to the direction of parting direction, the draft angle should be considered in advance.

6. Adding details and adjustments

Once the parting is done, small details such as rivets, lifting buckles, scribed line and grooves will be added.

For example, most details on the surface of the shoulder armors and weapons in the picture were added after the parting. If you check the pictures on Kickstarter, you will find that they are more detailed.

Most details are designed to make the model look more sophisticated. Especially on those large and empty surfaces, adding a little detail could put the finishing touches on the models.

Others are pragmatic, like fixing the shoulder angle or, most commonly, preventing sink mark.

If there is a thick reinforcing bar or locating dowels on the back of a thin part, we will put grooves on the front to avoid shrinkage, which will lead to depression and then sacrifice the aesthetics. The brand-new designed Type-77 Heavy shield in the picture is a typical example. In order to ensure that the shield itself and the additional armor are consistent with its setting as “building material”, we added a lot of reinforcing bars and also made many grooves correspondingly.

7. 3D Printing

After all the work is done, 3D printing allows us to conduct a practical verification, just to guarantee the aesthetic appearance as well as the assembly experience.

8. Transferring data to the factory

Then, we will send the industrial model files to the factory, and the engineers will check the shrinkage of the parts, draft angle and the feasibility of other parts with their professional skills and rich experience.

The figure above shows the analysis of the thickness of the front chest part of Lei-Gong’s outer armor. The red arrows point out the area where the shrinkage possibility is high. Then we will modify our design to avoid errors like this.

The main part of Heavy Shield is better, but there were still red areas. Later we made modifications and added some recess.

The engineers would give modification suggestions in the form of pictures and texts, and we have to go back to step 5 to 7. Mostly the modifications were not that complicated. When it was, we would discuss back and forth to find the most feasible solution.

9. Making the moulds

Well, it means making the moulds.

Here’s a little tip: In the production process of military module, most parts are not processed directly by CDC. Instead, the produce the copper parts first, and then use electric sparks to shape the steel module. It might sound troublesome, but the outcome turns out magnificent!

10. Trial production and modification

That’s all for module productions. However, few modules could come out perfect the first time, so the factory will use these new moulds to produce what is called T0 products. Then the parts will be sent to us and we will try to find problems in terms of combination and surface details during assembly.

We will make a modification report based on the assembly process, and then the factory will make adjustments accordingly.

T0 is followed by T1 and T2. The process is conducted repeatedly, and the sample parts and modules will be closer to perfection each time. Finally, when everybody is content with the results, this version of moulds will be officially delivered.

That’s all for the process of module development. Finally, please allow me to apologize again for the delay which is mainly due to the lack of experience instead of the epidemic effects.

We’ve always been learning from mistakes. Now the process is gradually optimized, and the efficiency has been improved. So, we sincerely hope that given more time, we will complete the production as fast as possible. We believe that Obsidian Protocol will soon be available!

Sehr interessant!

Opsidian Protocol ist ein Kickstarter bei dem ich sehr Bereue nicht dabei gewesen zu sein. Hoffe sehr das Im Handel nachzuholen.

Wie kann man hier einen sabbernden smiley einfügen?

🤤

Den hier?

Genau

Die Smartphone-Tastaturen haben seit ner Weile nen Smiley-„Button“ (vielleicht von Applet zu Applet verschieden).

Am PC wüsst ichs auch gerade nicht 🤷♂️

Am PC über die Bildschirmtastatur.

Wobei der Smiley hier auf meiner Faselfunke nicht angezeigt wird…

Jup. Ich freu mich auch schon sehr drauf!